Description

Product Description

- Inlet air temp reduction (IATS) of up to 58%

- Made in the UK

- 76mm inlet and outlets (OEM 63mm)

- 83% volume increase over the OEM

- No cutting of the vehicle 100% plug and play

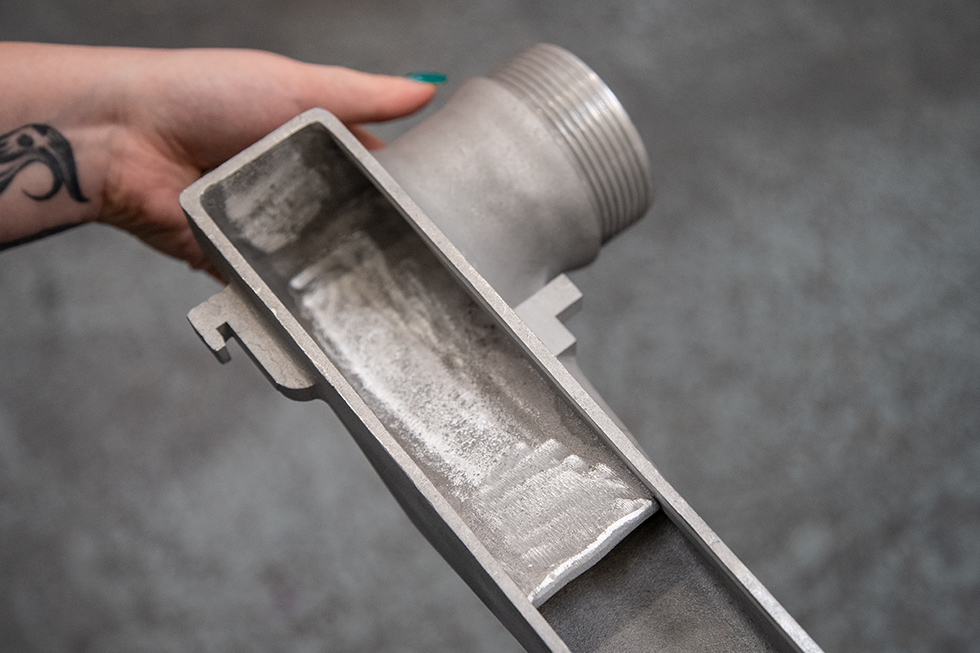

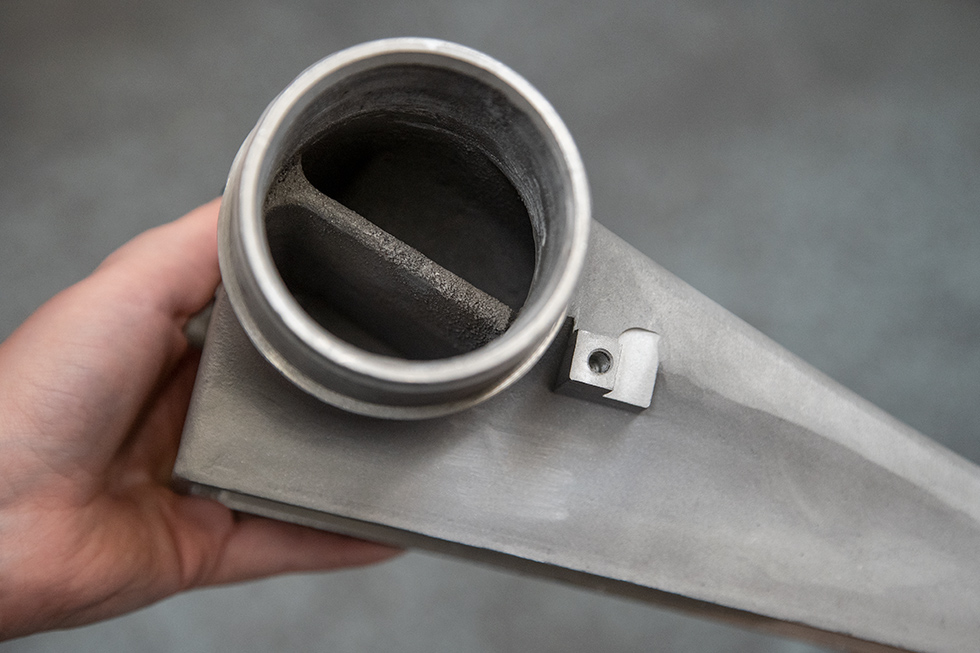

- High flow baffled cast end tanks ensuring optimum air transition for cooling efficiency

- 5 ply silicone hose kit included.

- Lifetime warranty

With our extremely successful product line up for the Audi 2.5 TSI equipped vehicles it was logical that Forge Motorsport to do the same with the Cupra Formentor VZ5, as it shares the same heart as the Audi’s RS3, However it may have the same 2.5 TSI engine but the cooling package is fitted to the VZ5 is not! The VZ5 actually has the same intercooler setup that can be found in the Golf R/Audi S3 so what we have here is a hybrid of two platforms. In our development of both the 2.5 TSI and 2.0 TSI we found the intercooling to be a compromised area and were able to extract large gains with our Forge cooling products for both engines,

Our development engineers have great experience of these previous models to take on the challenge of designing a vastly improved cooling package for the Cupra Formentor VZ5. The outlined brief was to develop an intercooler which utilises the maximum of the space available without modification to the vehicle and ensure a reduction in inlet air temperatures without any negative effects on turbo boost pressures and have scope for high levels of tune of 600 BHP and beyond.

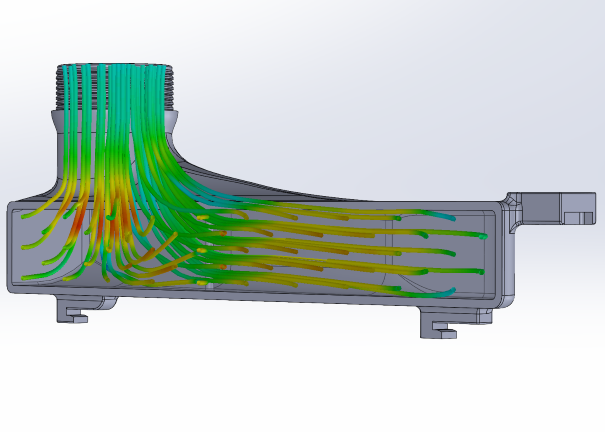

Several baffle configurations were designed, and flow simulated to ensure the maximum performance was obtained to keep the core working at its optimum, along with ensuring all its cooling capabilities had been upheld, and that the total volume of the core internal is utilised for optimum performance.

With an increase in inlet and outlet sizes, we then turned our attention to the design of our silicone hoses. With flow in mind, we have created a step within the hose so where the hose meets the hot and cold side of the inlet and outlet junctions the transition is seamless, this helps to lesson any disturbance to the airflow and prevent unwanted turbulence. To further aid with flow, the inlet and outlets have been increased to 76mm from the OEM size of 63mm which equates to a 45% increase in surface area.

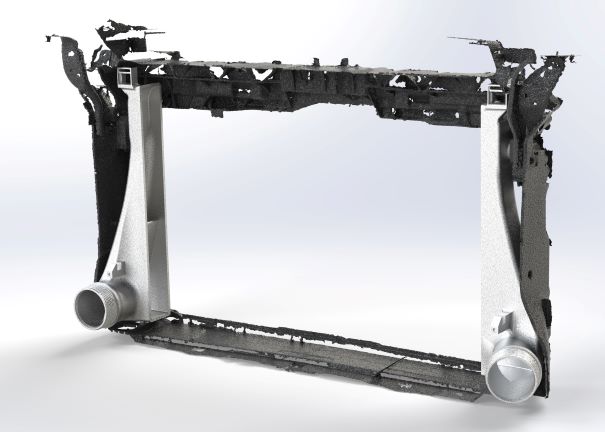

Unlike The Audi RS3/TTRS the Formentor VZ5’s intercooler housing is particularly restricted and confined to a small amount of space, due to it not only housing the intercooler, but also the radiator and air conditioning condenser. The front panel in theory is a sandwich pack that houses the auxiliary cooling components. This means in order to increase the size of the intercooler without paying detriment to the performance of the surrounding items, and with also having very little extra space available, that it can be very difficult to execute the perfect blend of a high flow intercooler within such a close proximity.

Using a combination of scanning software and traditional measuring methods, the design was created. This was then fine-tuned by our flow dynamics simulations programs (CFD), and the end tanks were initially created by 3D printers. This enabled us to ensure the fit was perfect on the vehicle before any prototype castings or machined billet end tanks were produced ready for dyno testing.

Several baffle configurations were designed, and flow simulated to ensure the maximum performance was obtained to keep the core working at its optimum, along with ensuring all its cooling capabilities had been upheld, and that the total volume of the core internal is utilised for optimum performance. To further aid with flow, the inlet and outlets have been increased to 76mm from the OEM size of 63mm which equates to a 45% increase in surface area.

With the end tank design completed we set to look at the boost hoses as the OE hoses are not compatible due to the forge increased inlet and outlet junctions, not to mention their single ply rubber construction which is susceptible to failing on tuned vehicles. Again, our in-house CAD designers have produced a product which incorporates a stepped join to create a seamless transition from boost hose to intercooler allowing the boosted air to travel as efficiently as possible and prevent unwanted turbulence. The construction is 5 ply silicone which is able to withstand boost pressures far north of what would ever be expected from this application. In the kit are supplied stainless steel Mikalor hose clamps to ensure a secure fit

The consideration of space and our clever design has led us to produce several intercooler cores with different fin configurations and internal capacities. Depending on the core design, testing results led us to choose a bar and plate design with over 83% more volume than the OEM intercooler, and with a frontal area increase of 10%

Why do we test different cores?

Here at Forge Motorsport, when developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, a tube and fin style core along with different fin pitches and heights, as well as changing the internal fin pitches/shapes and density within the tube; thus enabling us to fine tune the amount of pressure drop the intercooler produces. Pressure drop is not always a bad thing, as our testing and research has proven on various projects. This is because the pressurized air velocity is being stalled by the pressure drop within the cooler thus allowing more time to cool the air within the cooler itself, as air passes through the non-pressurized face of the core, that is open to the atmosphere.

Too much pressure drop can of course have a problem on the higher performance engines as the intercooler reaches its maximum efficiency the turbo has to work a lot harder to force the air through the core. This in turn creates higher inlet air temps (IAT’s) due to the turbo creating more heat as it is over stressed and worked harder. No pressure drop can also prove to be inefficient as the cooler will not lower the charge temperature again resulting in higher inlet air temperatures.

After more than six pulls on the dyno we still had super safe IAT’s, and the Forge Motorsport intercooler gave results of 34°C at 6548 RPM giving a reduction of 58% over the factory’s intercooler intake temps from 58°C at 6508 RPM. These tests took place in relatively hot conditions with an ambient dyno cell temperature of 23°C proving how inefficient the stock intercooler is.

In the summer months, the stock intercooler along with higher inlet air temperatures will have a hugely negative impact on the engine’s performance. In these conditions, the engine management will retard the ignition, resulting in a lower powered engine as temperatures rise and the ECU then pulls out the timing to stop detonation. On a mapped vehicle, the results will be even more detrimental and can lead to possible premature engine wear. If you use your car for fast road or have a high-performance tune in a hot climate, this product is essential.

Why do we try to decrease IAT's? (Inlet Air Temperature)

Temperature and volume of air supplied to your vehicles engine that is compressed by the turbo charger has a better effect on performance when cool as this is to provide the engine with more oxygen (denser air), thus improving the combustion in each cylinder. In addition, by regulating and reducing the air temperature, it also increases the reliability of an engine by keeping the AFRs (Air Fuel Ratios) in each cylinder at a safe level, which in turn, can increase an engines power due to the air being cooler. A bigger bang is then created within the cylinder, providing the correct amount of fuel is added. This can equate to an increase in BHP and torque.

In summary FMINT36 is the perfect performance enhancing product for your Cupra Formentor VZ5 which fits directly to the OEM mounting points, making for an straightforward install. No cutting of any components is needed, making the installation reversible if the vehicle needs to be returned to stock at any time in the future.

The Forge Motorsport design has utilized as much of the space available in order to offer the largest intercooler available for this platform, with much improved IAT’s and minimal turbulence and restriction FMINT36 is “the” product to unlock the full potential of the VZ5’s 2.5 TSI engine. If you are looking to tune your vehicle, then this product is absolutely essential.

The core and end tanks are finished in our black textured anti corrosion coating that also aids with its thermal properties and keeps the product looking that bit stealthier or OEM+. The silicone hoses are not only larger in diameter but also stronger with their 5 ply construction.

As with all Forge Motorsport fabricated items FMINT36 is hand crafted at Forge HQ in Gloucestershire. The Forge Motorsport lifetime warranty on all hardware products shows the trust we have in the quality of our products while they are being enjoyed on your pride and joy.

Click here to find out about information and care for your

Forge Motorsport cooling product.

Please Note: In line with our policy to constantly review, revise, and improve our product range, the appearance of the product you receive may differ from the one advertised.

Product Reviews

Product Reviews

Be the first to review this product

Want to leave a review?

Login

Register FREE!

Compatible Vehicles

Instructions

Intercooler For Cupra Formentor VZ5

Warranty

Warranty Infomation

All Forge Motorsport products come with a limited lifetime warranty. All warranty claims must be accompanied by the original proof of purchase to enable us to help you. Failure to supply this proof will result in your claim or enquiry being denied.

For further information, please call our customer service team on +44(0)1452 380999 or email info@forgemotorsport.co.uk.

Do not use aggressive (acidic) car cleaning products, particularly traffic film remover solutions or shampoos to clean your intercooler, radiator or oil cooler. The use of these products can damage Forge Motorsport cooling systems and invalidate your warranty. These are often found at car washes. A light, warm, soapy solution (free of harsh acidic cleaning compounds) should be used to clean you cooler and thoroughly rinsed away. We recommend that you should inspect your product on a regular basis for bent and/or crushed fins. Any bent fins should be carefully straightened to allow ambient air to pass through the core face. At the time of installing your Forge radiator, an approved coolant must be used and added to the coolant system. Be sure you never mix coolant and always use distilled water.

Shipping

Shipping

USA Deliveries

All Deliveries are sent via Fedex. We cannot guarantee delivery timelines as all orders are up to shipper schedules and routes. Delivery fee is a Flat Rate of $20 fo all orders over $20. Orders below that value are costed out based on weight. Signature required may be added to your package. Orders can not be re-directed, held, or re-scheduled.

Shipping outside of the Lower 48- Duty Charge Information

All Forge products are sold with a Delivery Duty Unpaid (DDU) status and an import tariff may apply to your order. Customers will be contacted by the Customs and Excise authority in the destination country regarding payment prior to delivery, and it is important that correct contact telephone number and email information be submitted with the order to facilitate this part of the delivery process.

Our shipping methods ensure safe and timely delivery of your new Forge products. For further information on cost and delivery times, please contact Forge using the info@forgemotorsport.com email address if you require any more information. We reserve the right to change the delivery service and company at any time.

***Once a product has left our warehouse and is in the possession of the shipping company, any claims must be made directly with that shipper however we can assist with most cases.

Visit our UK Site

Visit our UK Site

Visit our Asia Site

Visit our Asia Site